Rolls Royce’s Innovation Strategy

| ✅ Paper Type: Free Essay | ✅ Subject: Engineering |

| ✅ Wordcount: 3610 words | ✅ Published: 18 May 2020 |

Rolls Royce is a market leader in propulsion and distributed energy systems for both the defense and civil aerospace markets. Their commercial markets cover nuclear, gas turbine, and diesel technologies to power everything from small planes and trains to entire cities. The aerospace applications for innovation are where Rolls Royce has made significant investments and reaped interesting rewards. On the defense side of their business, they have over 16,000 engines in service. In the civil aerospace side of their business, they provide engines to airlines, private business and engines for helicopters.

Major changes in Industry

Beginning with the Innovation Portal Industry Patterns assigned reading, it is important to understand how the industry has changed. The nature of the aerospace industry has relatively high barriers to entry as the cost for entry is high and requires specific skills and expertise. Nonetheless, the industry has been experiencing growth as the demand for flights increases resulting in the rise of aircraft manufacturing (Bouchard, Murray, Stoessel, 2018). Several factors have contributed to uncertainty in the aerospace industry including: oil prices, continued regionalization, environmental concerns, and expensive maintenance costs (Bogaisky, 2018). The regionalization of airlines is leading the industry to seek lower operational costs and quicker turnaround times (Rosen, 2017). Additionally, societal demands have influenced change within the aerospace industry by demanding quieter engines. With customer demand high and the emergence of new digital and robotic technologies, the industry is beginning to undergo a disruptive period, which is changing the way companies such as Rolls Royce are doing business.

Major New Technologies

The advent of technological advancements in engine design and production, materials, data analysis, robotics, and after-market services is enabling the changes within the aerospace industry. Rolls Royce is a market leader in aircraft engine design, production, and full lifecycle services. Therefore, it is influenced by technological changes to advance both its products and processes to meet customer demands.

All industries are being affected by the development of greater efficiency in electric and hybrid engines. The promise of efficient, quiet, and powerful electric motors, batteries, and power distribution systems is breaking down a dominant design within the aerospace industry, the gas turbine engine. As gas turbines ushered out the turbojet and rotary engine before it, electric and hybrid engines are more efficient and are developing quickly for smaller aircraft which will likely become a disrupting innovation in the near future.

Additive manufacturing is another technology changing the aerospace industry. This technology employs lasers to fuse alloys together to assemble new designs from metal dust. This is being used today across the industry to aid in the production of complex parts for manufacturing jet engines, such as turbine fan blades and fuel nozzles. Additive printing also can be used to make previously complex parts out of a single piece of metal which enables lighter, less complex parts, which leads to greater fuel efficiency (Sutherland, 2019). By incorporating this technology into current designs and process, the companies can be more efficient in the way they manufacture the engines and develop more complex fan blade shapes to produce more efficient airflow which was previously unavailable with the previous dominant design, machine milling.

Improved fuel efficiency and lower emissions is one of the demands in the industry. This is one area where we’ll continue to see a shift with the emergence of new technology and innovation, as we do today in other industries. Just as the auto industry is experiencing shifts in producing more fuel-efficient vehicles, we’ll also see this in the aerospace industry. This shift is already beginning to occur today with the development of engines that are more fuel efficient and are designed to reduce CO2 emissions. In addition, the engines are also being designed to reduce noise. Rolls Royce has a goal to reduce CO2 emissions by 75%, noise by 65% and fuel usage by 30% (Rolls Royce, 2019).

One of technological shifts that is occurring is the change in how companies are using data. The emergence of artificial intelligence is allowing companies in the aerospace manufacturing business to change their business model and the way they do business. Rolls Royce recently introduced their R2 Labs, which is dedicated to improving their design, manufacturing and operational efficiencies by applying artificial intelligence and machine learning approaches to the vast amount of data they have collected (Tate, 2018).

The use of automated and intelligent robotics is a major new technology across many industries. Robotics are best known for their use in manufacturing, but new concepts are being developed to perform inspections and repair of delicate aircraft engines. Furthermore, the use of robotics allows machines to get to places humans previously could not without taking the engine apart. This innovation will allow swift inspections and turnaround times for defective engines, thereby increasing reliability and decreasing maintenance time.

The industry is also being transformed by offering more than just the product, which is the jet engine, but offering services that come with the product. This is one of the ways the players in the market are keeping sustainable growth (Bouchard, Murray, Stoessel, 2018). Rolls Royce introduced a program called CorporateCare which is an engine maintenance program offered to customers. This benefits customers by passing the handling of engine maintenance on to Rolls Royce. Rolls Royce also benefits from this program as it is able to leverage the data it obtains from this service for it’s engine health monitoring service (World Finance, 2016).

Main Market demands and how technology affects them

The aerospace market is primarily influenced by growing customer demand for flights, low-cost, and reliable service. Airlines struggle to provide high levels of on-time service because of the constraints of the current dominant designs. The airlines are thus leading the aerospace industry to explore how to provide more fuel efficient engines to reduce variable operating costs. The two main drivers of engine fuel efficiency are the weight of the engine and the amount of fuel it uses to create thrust. The cost of oil has been difficult to predict and recent price fluctuations are another reason for airlines to hedge against price variability with more fuel efficient engines. As described above, new engine designs, additive manufacturing, data analytics, and better maintenance enable lighter engine production and greater efficiency.

Another market demand related to cost is the lifecycle management of aircraft engines. As engines become more complex, more highly skilled labor is required to maintain and repair them. Additionally, the pace of change is quickening so engine mechanics have a more difficult time keeping up. After-market support services have been around for decades but new technologies in analytics and digital customer support are enabling predictive maintenance recommendations and virtual support services to improve costs and decrease maintenance down time. As previously stated, the development of advanced robotics is also contributing to decreased maintenance time and greater engine reliability.

The societal demands on the market are also driving changes. Environmental concerns dictate that companies be accountable for the creation of carbon dioxide (CO2) and nitrous oxide (NOx). Both of these by products of oil burning engines has been related to global warming and have created a market interest in the minimization of their production. Additionally, more people are concerned with the noise of aircraft, particularly as their arrive and depart airports in major metropolitan areas. The market demands that airlines minimize noise by using quieter engines or climbing and descending quickly from airports which requires greater thrust. Aerospace companies are therefore driven to incrementally improve existing engines’ noise profile whilst improving new designs to further minimize aircraft engine noise. New cowlings and reconfigured compression turbines are incremental design improvements, while electric engines are the gold standard for quiet operation. One needs only to stand next to a Tesla to understand the quiet advantages of electric engines.

How to Become a Market Leader

For aerospace companies to become market leaders, they will have to master both the incremental and revolutionary innovations that the market demands. Lower costs, greater reliability, lower emissions, and quieter operation are keys to mastering this market. Meeting lower costs involves lower engine and maintenance costs, more efficient engine operations, and improved designs to minimize emissions and noise.

Rolls Royce has taken important steps to explicitly improve efficiency and reduce noise. According to Rolls Royce, they seek to achieve 30% reductions in fuel oil usage and 65% noise reduction or 15db noise loss (Rolls Royce, 2019). The incremental design improvements in their Trent high-bypass gas turbine engine series takes advantage of three-shaft architecture, high efficiency core compression, higher pressure ratios, and advanced materials to withstand higher temperatures for longer times. Three-shaft and core compression advances create higher airflow bypass ratios which increases fuel efficiency by pushing more airflow through the engine at lower speeds. Higher pressure ratios and advanced materials cause more heat energy to be converted to thrust more efficiently thus reducing fuel use. Combine all of these technologies with additive manufacturing to create lighter turbine fan blades and assemblies to reduce overall engine weight causing even greater efficiency.

Revolutionary innovations are in earlier stages of development. However, Rolls Royce is working to develop its E-Fan X electric turbofan engines, ACCEL electric high performance engines, and hybrid electric vertical takeoff and landing (EVTOL) aircraft for commuters. These technologies seek to overthrow the fuel oil gas turbine dominant design for lighter, more efficient, and lower emission electric and hybrid-electric engines. These technologies also help Rolls Royce meet its environmental goals of reducing CO2 emissions by 75%, NOx by 90%, and noise by 65% (Rolls Royce, 2019). Due to the high demand or the rewards these innovations promise, Rolls Royce has partnered with European aerospace giant Airbus to develop these innovations in conjunction with new, more efficient passenger aircraft body designs. Additionally, since the dominant design of aircraft bodies and power distribution systems is based on fuel oil power, innovation in electric power designs will have downstream effects on aircraft design and production, making collaboration with aircraft producers all the more important (Rolls Royce, 2019).

The full lifecycle maintenance of Rolls Royce aircraft engines is another critical element to dominating the aerospace power market. Advanced analytics with artificial intelligence and machine learning are being used to improve operational efficiencies and development cycles (Tate, 2019). Furthermore, innovative robotics designs are in development to reduce maintenance time and reduce costs. Among these technologies are (Boon, 2019):

o FLARE – a snake-like robot in two parts that enters the side of the aircraft engine to repair expensive ceramic coatings and perform interior patches reducing time and cost

o Swarm – small, beetle-like robots used to automate interior scanning of engines to detect damage in a collaborative pact

o Cobra – another snake-like robot used to detect engine problems with an attached laser to conduct repairs

o Blisk Repair innovation – 3D modeling of expensive bladed disks used to compress air in engines and laser technology to rebuild the blades in place without having to replace the entire disk.

Process Innovation

Data analytics and innovation are core to their business. They have integrated data across all aspects of their business from design, manufacturing and how they interact with their customers. They’ve adopted an agile approach where teams run 90-day sprints to explore new ideas and determine which ideas are worth pursuing. (Rolls Royce, 2017).

In a video clip of Rolls Royce’s Scrum Master, Steve Rawlinson he speaks to the agile approach Rolls Royce uses and the culture change this brings. He describes the culture as being one where employees are engaged, open to change and willing to learn from each other. This fosters a collaborative and innovative environment that better enables them to adapt as technology changes and allows them to be more competitive in the market. The agile approach allows them flexibility and the ability to get feedback more quickly from customers, which is an important component to how they do business (Rolls Royce, 2019).

Another key component of their innovation process is drawing from the ideas of external sources such as smaller businesses and universities. Rolls Royce has developed research centers across the world through partnerships with universities. This enables them to draw knowledge from external resources and technology experts in the field (Rolls Royce, 2019). Rolls Royce also partners with many companies which further contributes to their knowledge base. In an article on their website, Caroline Gorski, Director of Global Ecosystem and Partnership, states that by the end of 2018 they planned to have “500 innovative businesses around the world on our books” (Rolls Royce, 2019). Rolls Royce’s absorptive capacity is a strength of their innovation process that propels them forward and provides them with a competitive advantage.

4Ps Approach to Innovation Strategy

Building a capability to organize and manage innovation is a great achievement, but one also needs to consider where and how innovation can be used to strategic advantage. Innovation can take many forms but they can be reduced to four directions of change: product, process, position and paradigm innovation. Product and process innovation were mentioned earlier, but Rolls-Royce made changes to its underlying mental model which frames what the organization does and how it creates revenue (Paradigm Innovation).

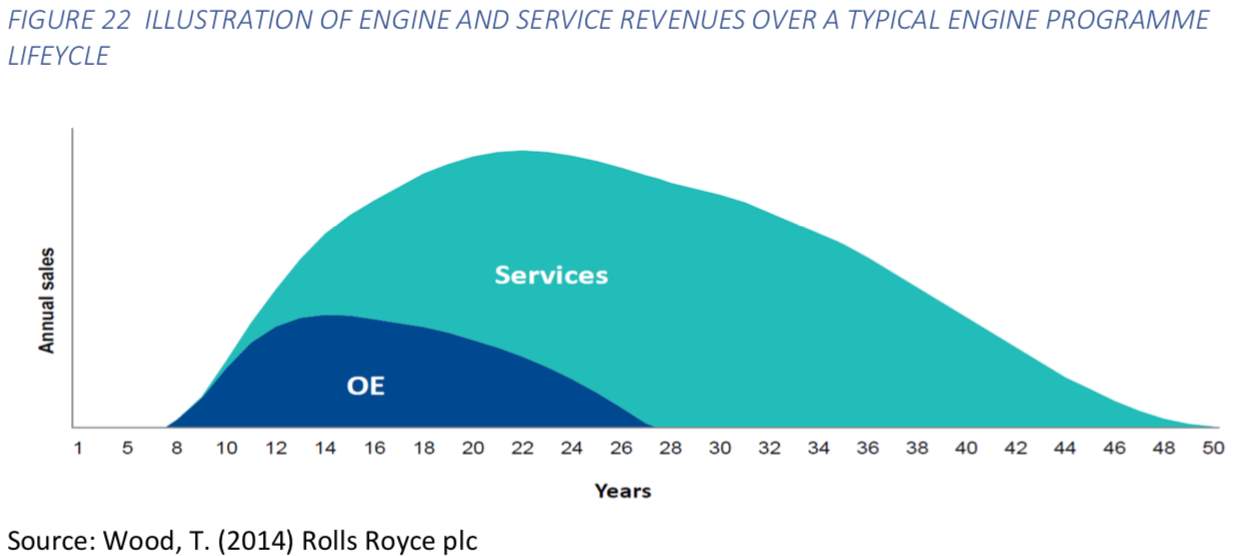

The cumulative effect of advances in engine technology meant that by the 1990s when the first of the current generation of engines like Rolls-Royce Trent entered service, they not only exhibited a level of performance in terms of thrust and fuel efficiency that was a substantial improvement on 30 years earlier, their durability was also vastly improved compared to first generation turbofans (Smith, D.J., 2013). The extent of this improvement was reflected in the demand for spares to replace worn and damaged components. Even in the early 1980s a jet engine would consume a quantity of spares equivalent to the original value of the engine in about eight years (Whitford, 2007), but engines like the new Rolls- Royce Trent that entered service at the end of the 1990s consumed this quantity of spares, not in eight years, but 25 years. For the engine makers this represented a very big drop in demand for spares and therefore their revenues (Smith, D.J., 2013). Faced with this, Rolls-Royce began to revise and re-shape its business strategy to be “customer centric” instead of “product-centric.” (Pugh, 2002). This aimed to extract greater value from one of the company’s most important assets, namely its installed engine base. Manufacturers were no longer looking simply to develop and extend their geographical coverage, but also the commercial scope of their after-sales activity.

Rolls-Royce has maintained its position as the market leader in business aviation engines through its trademarked CorporateCare (TotalCare) – the industry’s most comprehensive and cost effective engine maintenance program (Rolls-Royce, World Finance). Although Rolls-Royce engines are sold to the aircraft owner, the CorporateCare service packages means the Rolls-Royce retains responsibility for ensuring the product performs to customer requirements. The power-by-the-hour charging mechanism (revenues generated per engine flight hour) keeps incentives aligned by rewarding Rolls-Royce when the product is working as needed, and penalizing it when it is not (Smith-Gillespie, A., 2019). This mechanism and alignment between the OEM and its customers encourages continuous improvement and collaboration. This also drives the extension of asset lifetime while optimizing and reducing repair and maintenance costs. This results in reduced waste, increased resource efficiency, and enhances the asset’s value over its lifetime (Smith-Gillespie, A., 2019).

Advancements in technology, specifically digital electronics have been a powerful enabling factor facilitating the implementation of service strategies. This provided original equipment manufacturers (OEMs) like Rolls-Royce with a competitive advantage relative to conventional service providers, by enabling them to acquire new knowledge management capabilities (Smith, D.J., 2013). These technological advances allowed new service-focused offerings, enable the manufacturer to gather data on the use and performance of their products. In 2012 Rolls-Royce introduced its automatic Engine Health Monitoring data downloads for aircraft (G650, 550, 450). As such, there is an ongoing focus for the company to reduce the need for manual downloads, while also improving its overall data acquisition from in-service aircraft. (Rolls-Royce, World Finance).

Airlines face a number of risks and uncertainties in managing and operating their engine assets, with knock-on consequences for their operating costs and aircraft performance. One of the reasons Rolls-Royce is able to develop and deliver these services and offer them through the CorporateCare model is the intimate knowledge it has of its own engines and how they perform throughout their lifetime (obtained via engine health monitoring and MRO services). Through this, Rolls-Royce is able to offer customers support and services for better operational decision-making and efficiency (Smith-Gillespie, A., 2019). The value generated for airline operators from this service model are predictability of MRO-related costs, high operation efficiency, avoided disruptions, higher value of engine asset, and the ability to focus on their own resources and core business (Smith-Gillespie, A., 2019).

Customers become more sophisticated so their expectations rise and they demand solutions rather than mere products. The power-by-the-hour service model drives recurring revenues primarily by charging customers on the basis of hours flown by each engine it serves. Over the lifetime of a typical engine program, this translates into a volume of revenues which is approximately four times as large as that of the initial engine (original equipment) sale, as shown below (Smith-Gillespie, A., 2019).

High Involvement Innovation

John Bessant introduces four levels of innovation in his book “High Involvement Innovation.” The four level framework to define the evolution of high involvement innovation through various levels of development.

Level 1 – Little or random innovation involvement. People solve problems in an ad hoc and there is no structure around the activity. The innovation yields short term benefits but no strategic impact.

Level 2 – The first attempt to formalize the innovation process is made. Including a process to identify and solve problems and a reward system. They system may have facilitators but is often concentrated at the local level. The innovations have minimal impact on larger organizational goals. Without a specific set of targets the process is easy to abandon.

Level 3 – Includes level 2 and the innovation ties into the strategic goals of the organization and has a significant impact on the bottom line through new products, process improvements, etc. A limit of level 3 is predefined limits and definition by management.

Level 4 – Includes level 3 but the differentiator is empowering groups and individuals to innovate and experiment on their own. It fits with the idea of ‘internally directed’ innovation and “fast learning.” It is often associated with professional research scientists or engineers.

Rolls Royce operates on a 20 year innovation timeline. They break it down into 3 key milestones; five, ten and twenty year horizons. The five year technology is about innovations that are currently controlled and are currently being added into the products. Ten year technology is valid, leading edge technology that will impact the next generation of products. Twenty year technology is emerging and unknown but needs to be continuously searched for and monitored. (https://www.rolls-royce.com/about/our-research)

In 2015, CEO Warren East, described innovation as “the life blood of a successful company.” To support and foster innovation Rolls Royce has several systems to promote and track ideas for innovation; intranet sites, innovation portals, support forums, and innovation ambassadors. The company also provides time and resources to encourage and enable employees to get out of their day to day work and work on other areas of the business. The knowledge generated in the innovation platforms is then shared across projects and teams to ensure that useful ideas are not wasted and innovations can spread freely between teams. https://www.rndtoday.co.uk/latest-news/managements-role-is-to-nurture-innovation-says-warren-east/

Rolls Royce is clearly at level 4, ‘proactive/empowered high involvement innovation’ on Bessants scale. The organization, research and development, and tracking of their innovations meets all the criteria for level 3. Level 4 is met by management’s commitment to making innovation a part of the larger strategy, coupled with their resources and time for people across the company to experiment and transfer ideas and knowledge.

Bibliography

- (2016, March 8). Rolls-Royce is Driving the Progress of the Business Aviation Market. Retrieved from World Finance: https://www.worldfinance.com/markets/rolls-royce-is-driving-the-progress-of-the-business-aviation-market

- Bogaisky, J. (2018, December 26). What’s Ahead For Airlines And Aviation In 2019. Retrieved from Forbes.com: https://www.forbes.com/sites/jeremybogaisky/2018/12/26/whats-ahead-for-airlines-and-aviation-in-2019/#f806f52d172b

- Boon, T. (2019, June 13). Rolls Royce To Revolutionise Engine Maintenance With “Snakes And Beetles”. Retrieved from Simple Flying: https://simpleflying.com/rolls-royce-engine-maintenance/

- Bouchard, J., Murray, G., Stoessel, L. (2018, September 4). How Customer Demands And Digitalization Will Transform Aerospace Over The Decade. Retrieved from Forbes: https://www.forbes.com/sites/oliverwyman/2018/09/04/how-customer-demands-and-digitalization-will-transform-aerospace-over-the-decade/#45642dbe2fdb

- Rolls Royce. (2019, September 7). Future of Flight. Retrieved from Rolls Royce: https://www.rolls-royce.com/media/our-stories/innovation/2016/advance-and-ultrafan.aspx#overview

- Rosen, E. (2017, September 23). 14 Ways Air Travel Will Change in the Next Decade. Retrieved from The Points Guy: https://thepointsguy.com/2017/09/how-air-travel-will-change-soon/

- Rolls Royce. [Rolls-Royce]. (2017, November 1). Rolls-Royce | Neil Crockett – Digital transformation and data innovation. [Video file]. Retrieved from https://www.youtube.com/watch?v=XDHf47Ni5uw

- Rolls Royce. [Rolls-Royce]. (2019, May 8). Rolls-Royce | Steve Rawlins, Scrum Master, Rolls-Royce. [Video file]. Retrieved from https://www.youtube.com/watch?v=n8urpmuPpe8

- Rolls Royce. (2019, September 19). Research and University Technology Centres. Retrieved from Rolls Royce: https://www.rolls-royce.com/about/our-research/research-and-university.aspx

- Rolls Royce. (2019, September 19). The Power of Collaboration. Retrieved from Rolls Royce: https://www.rolls-royce.com/media/our-stories/insights/2018/caroline-gorski-on-the-power-of-collaboration.aspx

- Sutherland, B. (2019, April 12). Your Next Flight Is Brought To You by 3D Printing. Retrieved Bloomberg: https://www.bloomberg.com/opinion/articles/2019-04-12/3d-printing-is-set-to-revolutionize-aviation-for-ge-honeywell

- Tate, P. (2018, December 8). Powering Data Innovation at Rolls-Royce. Retrieved from National Association of Manufacturers: https://www.manufacturingleadershipcouncil.com/2018/12/08/powering-data-innovation-at-rolls-royce/

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal